New Self-Healing, Carbon-Negative Material Could Help Fight Climate Change

"Material science has never produced anything like this."

Biology can often be the ultimate design inspiration. Most recently, engineers at MIT were able to take a leaf out of nature’s playbook to design a material that’s self-healing and carbon-negative. It’s a welcome new tool in the fight against climate change, and could one day replace emissions-heavy materials like concrete with a far more low-maintenance, environmentally friendly alternative.

In the new study published in Advanced Materials, chemical engineers demonstrated how to design a material capable of drawing climate-warming carbon dioxide from the air and then use it to grow and repair itself. The study, led by professor Michael Strano at MIT, breaks barriers in the field of material science, with an inexpensive, simple to produce, self-repairing polymer that needs minimal material.

“Our material needs nothing but atmospheric carbon dioxide and ambient light, which are ubiquitous,” co-author Seonyeong Kwak explains to Inverse in an email.

Self-healing properties often seem to be dramatic miracles reserved for the animal world, for example geckos growing back tails and starfish growing back entire limbs (or wilder still, limbs who grow back an entire body). Humankind has dabbled in regeneration, managing to design soft robots who can repair themselves and a self-healing phone coating to end nightmare of shattered screens. But previous methods often require external input, such as UV light, heating or a chemical treatment. This new polymer is far lower maintenance and has an easily-accessible, abundant energy source: carbon dioxide.

Two samples of the material are dyed yellow and blue to observe their fusion. Physically connecting the materials without GL results in partial repair, as shown in A. With GL, the material gains gains full strength.

Carbon-Eating Chloroplasts are the Key

“Imagine a synthetic material that could grow like trees, taking the carbon from the carbon dioxide and incorporating it into the material’s backbone,” Strano explains in a press release.

By taking advantage of chloroplasts, the component of plants that harvest and transform light into energy, Strano’s team made this possible.

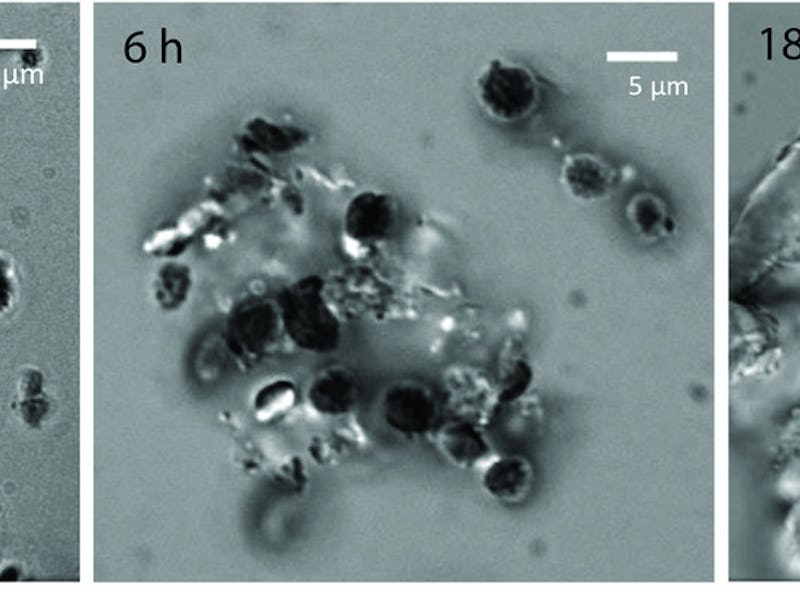

Suspended in the hydrogel is a polymer called aminopropyl methacrylamide (APMA), stabilized chloroplasts removed from spinach, and an enzyme called glucose oxidase (GOx). When exposed to sunlight, the chloroplasts produce glucose. Then the enzyme GOx kicks in, turning the glucose into gluconolactone (GL), which reacts with APMA to come full circle, creating the very material that makes up the hydrogel itself, glucose-containing polymethacrylamide (GPMAA). Researchers can literally see the material grow into a solid from liquid form.

Chloroplasts allow the hydrogel to use atmosphere CO2 to produce more hydrogel.

While they are key to the polymer and attractive because of their abundance, chloroplasts also presented challenging design issues. As biological components, chloroplasts aren’t motivated to function when separated from their plant homes — once removed, their photosynthesizing abilities last only a few hours to a day, maximum. For now, chemically treating chloroplasts increased stability and glucose production, but researchers hope to switch to a non-biological alternative.

Self-Healing for Sustainability

With growing urgency of to develop more sustainable methods of living, the polymer holds promise to help reset thinking about maintaining the built environment around us.

“Our work shows that carbon dioxide need not be purely a burden and a cost,” Strano says. “It is also an opportunity in this respect. There’s carbon everywhere. We build the world with carbon. Humans are made of carbon. Making a material that can access the abundant carbon all around us is a significant opportunity for materials science. In this way, our work is about making materials that are not just carbon neutral, but carbon negative.”

The material isn’t strong enough for large-scale construction, but short-term applications like filling cracks or to self-healing coatings could be realized in as few as 1-2 years.

“Materials science has never produced anything like this,” Strano told MIT News. “These materials mimic some aspects of something living, even though it’s not reproducing.”