PPE poses a major environmental threat — scientists propose a solution

"[W]e can foresee the issues of economic crisis and ecological imbalance."

An unfamiliar phrase to many at the beginning of the year, personal protective equipment (PPE) — a grouping that includes masks, face shields, and full-body suits — has become a familiar sight during the Covid-19 pandemic.

While this incredibly important equipment was scarce back in March and April, single-use PPE is now facing the opposite problem — it is seemingly everywhere, including places where it shouldn't be.

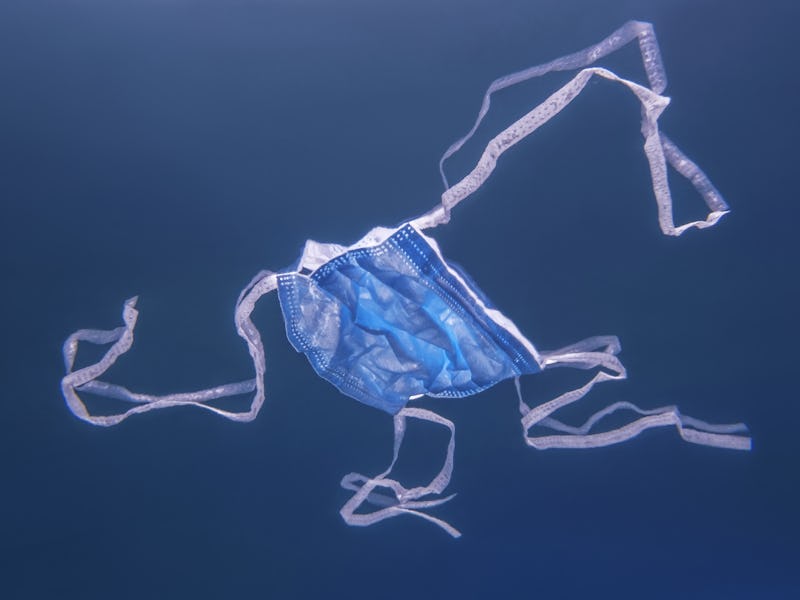

Now, it's not unusual to see masks discarded on the side of the road alongside crumpled fast food bags, or littered on the beach. With an approaching tidal wave of waste from this equipment, scientists are concerned about the impact it could have on the environment.

Researchers behind a new study propose a solution: They argue that this influx of discarded PPE could actually be good for Earth if transformed into biofuel using a simple chemical process.

In the study, published Monday in the journal Biofuels, a team of scientists from India describe a simple process that could transform the plastic material present in many PPE, polypropylene, into biofuel on par with traditional fossil fuels like diesel. This is the same kind of material used to make prescription bottles or yogurt cups.

The study's lead author and professor of chemistry, Sapna Jain, argues that sustainability cannot be overlooked, even when it comes to life-saving equipment like PPE.

"Presently, the world is focusing to combat COVID-19, however, we can foresee the issues of economic crisis and ecological imbalance also," she explains. "We have to prepare ourselves to meet the challenges which are forcefully imposed by the COVID-19 pandemic, so as to maintain sustainability."

But, lucky for us and the environment, the scientists say they didn't have to re-invent the wheel to find their solution.

A discarded face mask in Montenegro.

How does it work — Breaking down this type of plastic is a standard, three-step process that involves a lot of heat and breaking a few (chemical) eggs. It essentially comes down to:

- Initiation

- Propagation

- Termination

This process itself is called thermal pyrolysis. Initiation is when a plastic material is exposed to super-hot temperatures (between 572 and 752 degrees Fahrenheit) in order to produce free radicals. You might be familiar with free-radicals as the potential culprit of aging in our skin, but in a more general sense, they're just uncharged, single molecules who are very eager to find a partner (e.g. an extra electron). They are also willing to steal someone else's in the process.

After free radicals are released from the plastic, they are further broken down into smaller radicals and molecules during propagation reactions. Finally, these unstable free radicals are brought together in couples as part of the termination step.

The authors write that this process is not only standard but has the added benefit of not needing plastics to first be separated beforehand, meaning using mixed plastics (like PPE) would work just as well.

What were the results — After undergoing this chemical transformation for 60 minutes in an oxygen-free environment, the researchers report that this plastic turned into a biofuel with characteristics on-par with traditional fuels like diesel or gasohol. And with at least an 80 percent liquid yield, the process was able to productively use most of the plastic material.

Co-author and professor of chemistry, Bhawna Lamba, explains that this process could simultaneously address both problems of PPE waste management as well as those of clean energy.

"The challenges of PPE waste management and increasing energy demand could be addressed simultaneously by the production of liquid fuel from PPE kits," Lamba says. "The liquid fuel produced from plastics is clean and have fuel properties similar to fossil fuels."

The authors write that the biofuels created using this method could be used to fuel turbines, boilers, or generators. PPE conversion has the potential to not only "prevent the severe after-effects humankind and the environment," they argue, but to result in a new source of energy.

Abstract: COVID-19, a disease caused by severe acute respiratory syndrome-corona virus-2 (SARS-CoV-2) has taken the lives of millions of people across the globe. Researchers are working on the development of different aids to cure and prevent the disease. Personal protection equipment (PPE) has become an essential prerequisite for healthcare workers. PPE kits are reported to provide sufficient protection against pathogens but their disposal can be devastating to environment. The proper disposal of PPE is being taken care of by the national authorities according to the guidelines provided by WHO. The plethora of disposed PPE kits will further increase the burden of polymer on our earth. This review presents a strategy to dispose the PPE kits by their conversion to alternative fuel.

This article was originally published on