The Added Cost of Making an iPhone in America Isn't Ridiculous

Trump wants to force Apple to move manufacturing back to the U.S.

Republican presidential candidate Donald Trump wants Apple to manufacture its iPhones in the United States. Far-fetched as that is, it wouldn’t jack up the price of a phone by as much as you might expect.

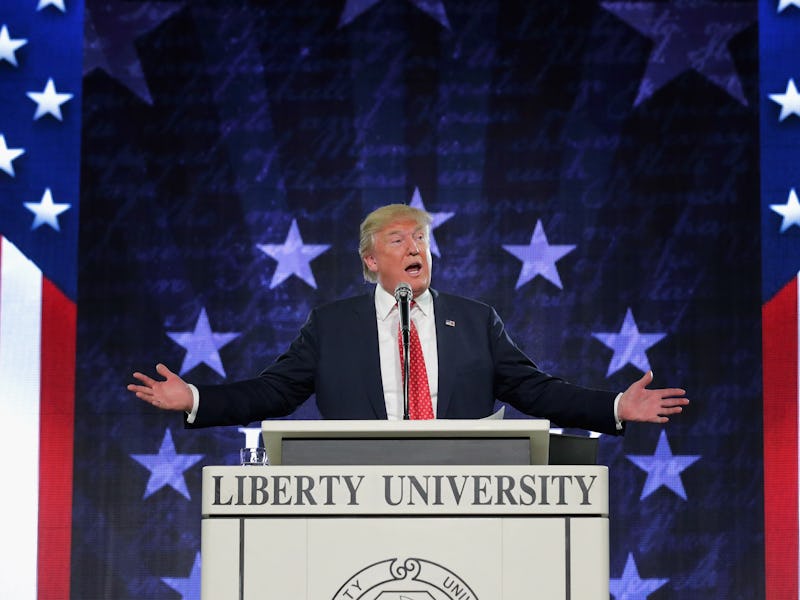

During remarks at Liberty University in Virginia on Monday, Trump went so far as to declare that, if elected, he would “get Apple to build their damn computers and things in this country instead of in other countries.”

Given the much-maligned, though also hotly debated, state of American manufacturing, it’s a sure bet that many people would like to see Apple bring more of its production to the United States. President Obama even asked Steve Jobs back in 2011 why Apple couldn’t make more of its products in the country.

His answer: “Those jobs aren’t coming back.”

The United States certainly has the technical capability to assemble the iPhone, but what’s not clear is whether consumers are willing to pay for the higher wages Apple would have to pay American workers compared to Chinese workers.

Motherboard went ahead and calculated how much more it would cost Apple to assemble their phones in America and found that American workers would require about four times more pay than Chinese workers. The working assumption is that Apple would shift assembly to the U.S. while most components would still be manufactured in China.

Assuming Apple didn’t take the opportunity to ahem gouge us any further, iFixit CEO Kyle Wiens told Motherboard the higher wages could lead to an additional $50 charge on the newest iPhones. So the iPhone 6s Plus would go for $800 instead of the $749 it retails for now. That’s hardly a crippling markup.

It might be optimistic though, considering the one example we actually have of a country — Brazil — convincing Apple to manufacture its phones outside of China. The 32 gigabit iPhone 5s retailed in Brazil for around $1,000, and the hoped-for boom in tech manufacturing also failed to materialize. That being said, iPhone sales have hardly skipped a beat, with consumers either appreciative of the locally manufactured tech or just as desperate as everyone else is to get a hold of the newest Apple gear.

Trump may try to force Apple to ship its iPhone assemblies to the United States by imposing the 45 percent tariff he spent much of the last debate denying he had ever endorsed. But even this proposal would only have a shot if he applied it to all countries, since plenty of other locales would likely be willing to offer the scale of manufacturing Apple wants for a similar low cost and wouldn’t be affected by a tariff on Chinese goods.

Whether or not American consumers would pay an extra $50 or more for made-in-America phones remains to be seen, but Chinese consumers would almost certainly be disappointed by the higher cost and loss of jobs. And Apple may be willing to deal with some bad publicity in the United States to keep its next-largest and fastest-growing market happy. So Apple could split the manufacturing between the two countries, though doing so would limit any real benefit to American manufacturing, and obscure what many experts say is the main benefit to producing everything in the same place.

According to a New York Times article on the same topic:

“It isn’t just that workers are cheaper abroad. Rather, Apple’s executives believe the vast scale of overseas factories as well as the flexibility, diligence and industrial skills of foreign workers have so outpaced their American counterparts that “Made in the U.S.A.” is no longer a viable option for most Apple products.”

Admittedly, there’s something to be said for dreaming big, and no one can dispute how Trump feels about dreamers.