The First Pieces Of The World’s Largest Telescope Just Arrived In Chile — And They Are Gorgeous

You might even call it extremely large.

The first mirrors for the European Southern Observatory's Extremely Large Telescope (ELT) arrived at the scope’s future home in Chile just in time for Christmas, but the unboxing process is going to take a while longer — and there's definitely some assembly required.

The 18 mirrors that sailed halfway around the world in late December are just the first of 798 hexagonal pieces that will eventually combine to form one, well, extremely large 128-foot-wide mirror. If everything goes according to plan, that giant mirror — the largest optical and infrared telescope mirror in the world — will start gathering light from alien worlds, ancient galaxies, and supermassive black holes in 2028.

This is what ELT’s primary mirror segments look like before polishing at the Safran Reosc facility in France.

Hundreds and Hundreds of Hexagons

Even with the best modern glassworking facility, casting a telescope mirror larger than about 26 feet wide is still impractical. Most of the world’s largest telescopes have main mirrors that are really assemblies of many smaller mirrors, carefully aligned and mounted on a frame. Each of the ELT's mirror segments is about 4.5 feet wide and less than two inches thick. The surface of the glass has to be perfectly smooth, and the margin for error is astronomically tiny: less than one-thousandth the width of a human hair.

"To achieve the required optical performance, the segments must be figured with a precision within fractions of the light wavelength. The average required surface quality of the segments is 15 nanometers," Marc Cayrel, optomechanics project manager for the ELT, tells Inverse. "The full width of a human hair is about 70,000 nanometers."

The mirror segments traveled from a manufacturing facility in Germany, where the glass gets cast, to another facility in France, where it's polished with a microscopic beam of ions, which, as the ESO puts it, "sweeps the mirror surface and removes irregularities atom by atom." This technique, called ion beam figuring, has been used on lots of other telescope mirrors, including those of the Keck Observatory in Hawai'i and the Gran Telescopio Canarias on the island of La Palma.

"The challenge has been to industrialize the existing techniques and processes so that the segments can be mass produced (to about one per day after ramp-up)," says Cayrel.

Each mirror is specially packed in its own shipping container before being loaded onto a cargo ship for the long journey from France to Chile.

Extremely Special Shipping

Each batch of mirrors, starting with the first 18, will have a long sea journey from France to Chile, and then a much shorter drive across the Atacama Desert to their eventual home atop Cerro Amazones.

Forget bubble-wrap and express mail: The mirrors must be shipped in temperature-controlled containers equipped with special air cushions, and each segment is tucked in a special bag filled with dry nitrogen to protect the thin sheets of glass from warping due to humidity or condensation, then installed on motion-dampers inside the container to protect it from vibrations, bumps, and other shocks.

"Although we maximize the protections of the segments, the maritime containers are transported to Chile using common commercial ships and routes," says Cayrel. "The risk of damage is normally very low."

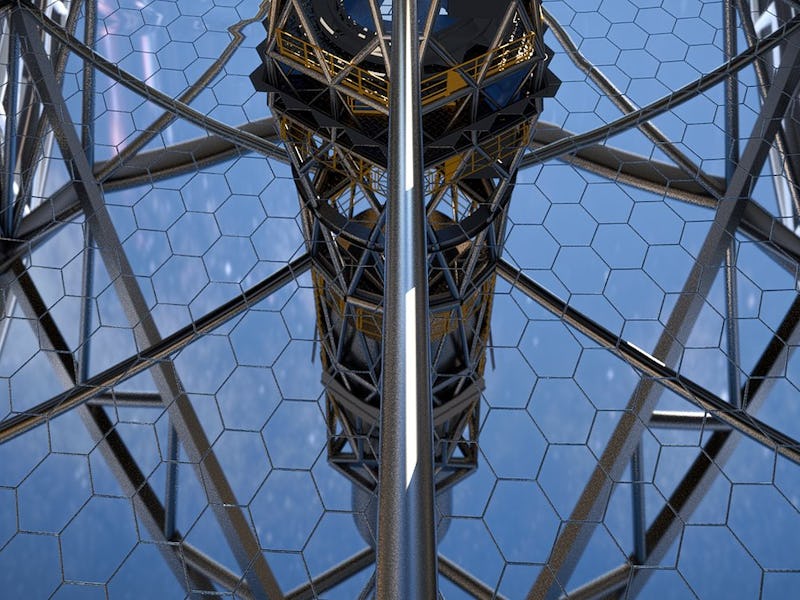

Each mirror segment fits into a framework like this one, to support it and help keep it aligned correctly with the other segments. Each of these assemblies weighs about 550 pounds.

Gift-wrapping in shiny silver

Now that they're in Chile, the mirror segments still need to be carefully coated with an extremely thin — 150 nanometers — layer of silver. The Very Large Telescope, an array of four 8.2-meter telescopes atop nearby Cerro Paranal, also managed by the European Southern Observatory (which definitely has a consistent naming system), uses aluminum for its mirrors' shiny metal coating.

"By using a more reflective silver coating, the ELT will be able to gather more light — allowing ESO astronomers to observe the night sky in astonishing detail," says Cayrel.

The silver coating will stick to the mirrors' meticulously polished glass thanks to a technique called magnetron sputtering, which involves — to put it in very simple terms — applying a super-thin, super-smooth layer of silver to the mirror's surface in a vacuum.

Once coated, the first 18 mirror segments will then have to wait patiently for their 780 siblings to join them. Once they are all together, all and then all 798 glass-and-silver hexagons will be carefully aligned to form the primary mirror of the ELT. That mirror will capture light from distant objects and reflect it onto a secondary mirror which, in turn, will reflect it onto instruments that will help astronomers make sense out of all those pixels.