The Next Goal for Moon-Landing Robots: Assembling Ikea Furniture

Today the living room, tomorrow the stars!

How much does building Ikea furniture have in common with landing on the moon? Not a whole lot if you’re a person, but quite a bit if you’re a robot. An unpublished study recently uploaded to the ArXiv repository details an effort to make a robot accomplish one of the most singularly important tasks for all of Western civilization: assembling a single goddam piece of Ikea furniture.

While a lot of humans think robots will be taking over their jobs in the near future, the truth is that robots still have a long ways to go before they can take over many of the physical jobs or tasks humans are able to do with very little brain power. It’s certainly not a matter of strength — a machine can always be made to lift and move objects around infinitely better than any mere person could.

No, the fact is we still haven’t created a robot that posses the finesse and precise capability to pick up, move around, and place an object in the correct spot. Teaching a robot hand-eye coordination is incredibly difficult. Teaching them to make sense of a set instructions drawn by the Swedes is also a pain in the office. That means the process of building anything that doesn’t require the same exact motion and movements for each step is virtually impossible.

So robotics engineers Francisco Suarez-Ruiz and Quan-Cuong Pham at the Nanyang Technological University in Singapore want to teach a robot those things, using our Ikea chair assembly as a litmus test.

If they get it right, an unintended consequences will be that their robot will be a few steps forward in knowing how to land on the moon. That’s because for a robot to land on the moon, it needs to exercise precise control over its motion, position, coordination, and be able to identify and adjust to surrounding objects — the same things that would make it an excellent furniture assembler.

The robot the pair of Singapore researchers are using has two arms that exhibit six-axis motion, with parallel grippers to grab and release objects. Suarez-Ruiz and Pham have outfitted the the grippers with pressure sensors, as well as a vision system comprised of six cameras.

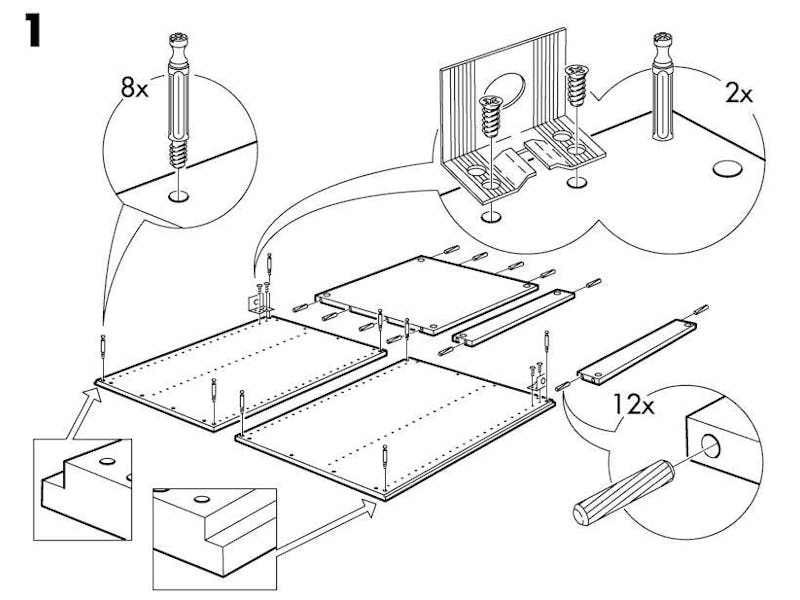

As is the case with Ikea furniture, the robot is made to accomplish various building tasks like screwing things together, inserting objects into other places, and so on. A good example, in the case of this chair, is sticking dowels into wooden holes. The robot needs to do three things to complete this task: locate and pick up the dowel, locate and pick up the wooden object with a hole, and put them together.

It’s sounds stupid easy to us. For a robot, it’s the Mount Everest of challenges. The robot needs to identify the dowel of the correct size first. It needs to grip the dowel firmly enough that it will have enough force to push it into the circular hole, but not so much force that it could break the stick in half. It also needs to locate the hole itself.

You can’t simply pre-program these sequences. The robot needs to be able to do these things in a variable environment — as would be the case for a robot trying to land safely on the moon. All the researchers can do is make modifications to the automation parameters that govern what the robot does (or tries to do), in hopes that it will take a more accurate, efficient action next time. It’s an intense trial-and-error process.

So if the researchers finally make their robot build a chair, does that mean they can launch it into space and watch it sail onto the lunar surface like a champion. No way. But, what it does mean is that the robot will possess the correct design that makes it able to move with a very high and very sensitive degree of precision. Any space roboticists looking to send their little minions out to the moon will want to take a look at what the Singapore engineers were able to accomplish and borrow some of that programming for themselves.

And, if that happens, you might be able to say the Swedes have finally landed on the moon.