Design

This biodegradable filament makes 3D printing more environmentally conscious

But "biodegradable" doesn't mean you should throw your 3D-printed goods in the backyard.

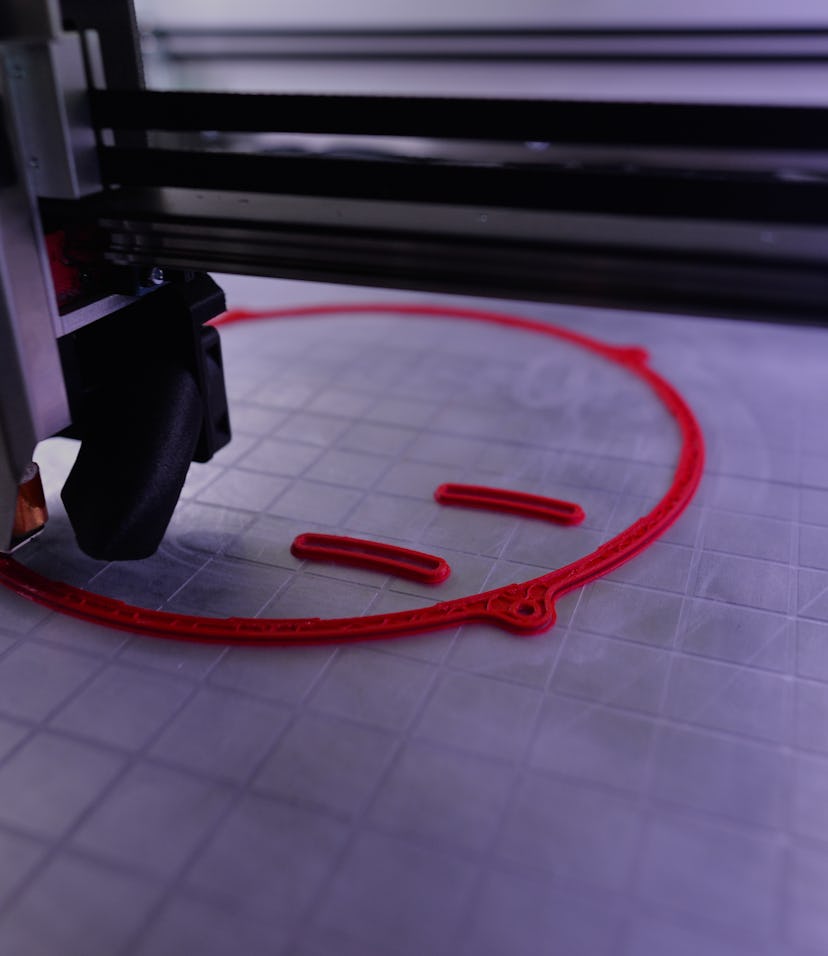

A company called Fillamentum has created a new material for 3D printers that can be used to print objects that are biodegradable. The filament, or a stringy plastic that’s used to make objects, is called NonOilen, and is made of a biologically based polylactic acid and polyhydroxyl butyrate blend.

Bioplastics — According to the company, NonOilen is food safe, meaning you can make cups, plates, and cutlery out of the plastic without risking exposure to toxic chemicals. But the most notable thing about the material is that it’s supposed to be compostable, meaning it can be broken down and reused in new objects, or converted into biomass like compost.

Often called “bioplastics,” materials like NonOilen can be more eco-friendly than traditional plastics — in theory. One study from 2017 found that switching from traditional plastic to a bioplastic like NonOilen could cut overall greenhouse gas emissions by 25 percent. Because they use organic material, bioplastics only emit as much carbon dioxide as the natural plants they’re derived from used in order to grow. But the tricky thing is that reusing or composting bioplastic after production is tricky.

Bioplastics are durable — you can’t throw them in your compost bin because they just won’t decompose quickly. Instead, they need to be sent to specialized facilities where high temperatures and oxygen enable bacteria to activate and break down the plastic. But those facilities are uncommon in the U.S, and bioplastics can’t simply be sent to the same recycling facilities used for traditional plastics. If the get mixed in a recycling bin with other plastics, the whole lot could be sent to a landfill where they’ll emit harmful gas and potentially leak into waterways.

American recycling is broken — Sadly, even when it has been properly sorted into the recycling stream, most recyclable materials never get recycled and end up in landfills. That’s because American waste processing companies have historically relied on China to recycle trash, but that country abruptly stopped taking foreign recyclables in 2017. The industry stateside was not prepared to take over because proper recycling is an expensive process and with China out, there wasn’t a big market interested in buying the material. Especially because “virgin” plastic is cheaper than recycled plastic.

Which is all to say that while biodegradable plastics like NonOilen are good in theory, they’re not 100 percent safe for the environment. The circular economy of plastics being used and reused is small.

Still, under the right circumstances, printing home goods using biodegradable plastics is probably better than the alternatives. And because 3D printing has brought down the cost of prototyping new products, those prototypes could be a bit more environmentally friendly now with a filament like NonOilen.