Researchers made a solar window by punching holes through silicon

Solar glass is going to change everything.

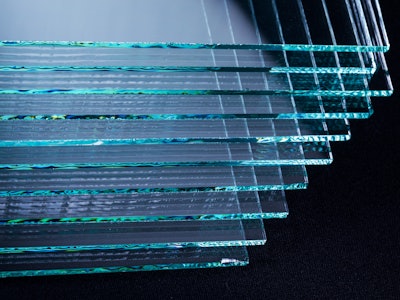

Researchers in South Korea have developed a new method for making solar windows. Correcting a well-known problem with transparent solar cells producing a reddish hue, these researchers discovered is that you can make a solar window simply by punching extremely small holes—the size of a strand of hair—into crystalline silicon wafers.

Crystalline silicon cells are the most popular type of solar cell in the industry. They found if the holes in the cells were properly spaced, you can’t see them with the naked eye. This research was just published in the journal Joule.

One of the researchers holding up the solar cell.

Kwanyong Seo, a professor of chemical engineering at the Ulsan National Institute of Science and Technology (UNIST) and one of the authors of the paper, said in a statement that solar windows are needed because traditional solar panels take up a lot of space.

“Current solar cells need space. On the ground or enough space on the roof,” Seo said. “But the roof ratio is getting smaller and smaller compared to the window area.”

A good solar panel has an efficiency of around 20 percent. The solar cell this team was able to develop reached an efficiency of 12.2 percent, which is pretty high. The researchers explain that transparent solar cells work perfectly well as windows because they don’t lose much efficiency by being placed vertically, as traditional solar cells do. A traditional solar cell loses 30 percent of its efficiency when it is positioned vertically, due to the angle of the sunlight, compared to 4 percent with a transparent solar cell.

The researchers believe they will soon be able to get the efficiency of this solar cell to 15 percent. They plan to scale up the project and see what it’s like to actually replace a window in a building with this type of cell.

Lance Wheeler, a research scientist at the National Renewable Energy Laboratory not involved in the study, tells Inverse that he’s impressed by the team’s results. He says it’s quite likely they could get it as high as 18 percent once they develop this concept more, which would be high enough to make this a desirable product. He says there’s a limit to how high you can get the efficiency with transparent solar cells.

“Theoretically, the best you can do is 20 percent,” Wheeler says. “So 12 is really not that bad. It’s pretty darn good.”

Quite a bit of research has been done in this area in the past. A team led by Richard Lunt, an associate professor of chemical engineering and materials science at Michigan State University, was able to create completely transparent solar glass using a thin film of organic photovoltaics that was applied to glass in 2017. However, this method of making solar glass only yielded an efficiency of 5 percent.

See also: See-Through Solar Panel Breakthrough Could Lead to Self-Powered Smartphones

Wheeler says this kind of technology will be great for powering high-rise buildings. As opposed to a house, these tall buildings have a lot of window space, so solar windows would produce a lot of energy. For a house, you’d be better off covering the roof in solar panels or installing solar roof tiles.

Solar glass won’t just be great for helping us power skyscrapers. It will be useful for helping charge parts of an electric car while you’re driving and devices like our cell phones when we’re out and about. As battery life goes up and solar glass technology advances, a dead battery might soon be a thing of the past.

Abstract:

Crystalline silicon (c-Si) is not used for developing transparent photovoltaics, owing to its opaque nature. Furthermore, adding optical transparency to a conventional c-Si wafer is one of the most challenging problems in this field. Here,we demonstrate the development of a neutral-colored transparent c-Si substrate using a 200-mm-thick c-Si wafer, which is known to be intrinsically opaque. Transparent c-Si substrates were fabricated by placing microhole-shaped light transmission windows on a bare c-Si wafer. These windows were designed to enable the transmission of all incident visible light through the substrate, resulting in a colorless substrate. A light absorption area was also designed on the wafer to efficiently absorb incident light. As a representative application, solar cells fabricated using the neutral-colored transparent c-Si substrate showed a power conversion efficiency of up to 12.2%. Therefore, our transparent c-Si solar cells present a unique opportunity to develop next-generation colorless transparent photovoltaics.